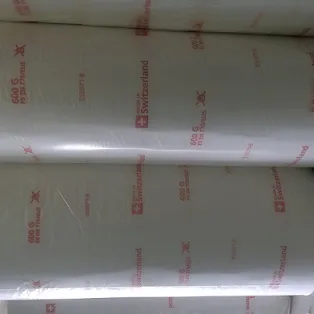

SPRAYBOOTH CEILING INLET MEDIA

Description

The 600G ceiling filter is an efficient filter for a consistent air stream through the spray booth. It is specifically designed for fine filtration of the air intake in down draft paint spray booths and aviation industry. Manufactured in Switzerland, with over 100 years of experience, filtration performance is guaranteed. SBCC 600G series is used by customers, with the highest standards like car manufacturers (e.g. BMW) and aviation service stations, all around the world.

Quality control testing according to F5EN779/EU5

EU5 fire classification and is self – extinguishing

Fully tackified

Protection cloth against mechanical stress

Constant low pressure drop

High dust holding capacity

Downloads

Product list

| Code | Width (mm) | Length (m) | Nominal Thickness | Efficiency |

| SBCC-600G-2000 | 20 | 20 | 18 | F5 |

TECHNICAL DETAILS

Typical filter-values according EN 779

Weight per square unit: 570 g/m²

Rated air speed: 0.25 m/s

Initial pressure loss: 35 Pa

Final pressure loss: 450 P

Initial dust weight arrestance: 93%

Average dust weight arrestance: 97%

Initial dust spot efficiency: 25 %

Average dust spot efficiency: 59 %

Dust Holding capacity: 340 g/m²

Temperature resistance: 100° C

Flammability class: DIN 53438 F1

Marking: “F5 EN779/EU5”

Special Features: Fully Tackified

Structure

- Optimal progressive structure and layers of different fiber deniers, thermo-bonded.

- Clean air side calendared and scrim (inter-laid) thermally bonded.

Characteristics

- Fully impregnated with ecologically sound dust binder (tackifier), migration proof.

- Migration test class S 0 (10 microns).

- Improved handling due to non-sticky surfaces, no oily hands and equipment

- Special rotary blade cuts.

Applications

- Ceiling filter media for paint spray booths.

Delivery form

- In rolls or cut to pieces

Frequent mistakes regarding Ceiling filters

The heavier a filter the better its performance?

No, there is no direct relation with filter performance on filter thickness. The efficiency of the filter is more of a result of the fibre build up and pore size.

The stickier a filter the better?

The oily or sticky filter is not a guarantee for filter quality. We use a special tackifier which has a waxy touch to it. A sticky substance is often cheaper and due to its stickiness, it is not possible to spread the substance evenly into the filter. If the filter media is completely drenched in the oily or sticky medium, the fibres in the filter clot and stick together. This creates a very negative effect on the filtration performance and consistence of the material quality. Often a sticky filter will use glue like substance which is mostly based on highly flammable chemicals. The tackifier used is not as sticky as glue. This prevents sticky hands while cutting the filter media and installation.

What are the determining factors for a filter?

- Filtration performance: The filter class (F5EN779/EU5)

- Life span: Dust holding capacity–how much dust can filter store away until it is full.

- Operation cost: Initial pressure loss–How big is the air resistance/energy consumption of the filter?