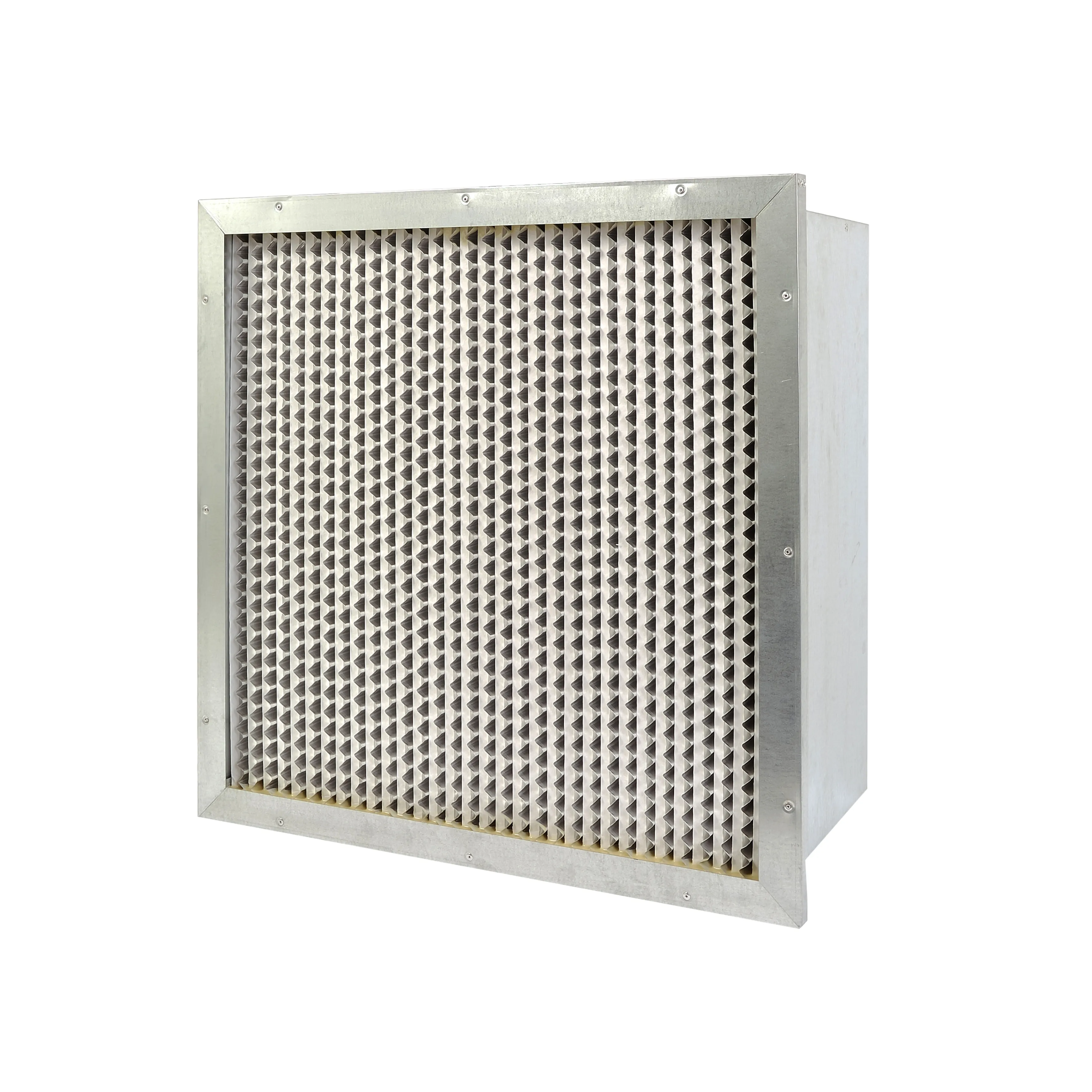

HEPA Filter with Aluminium Separator

Product list

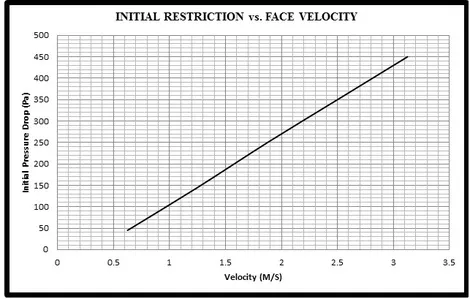

| Code | Width (mm) | Height (mm) | Depth (mm) | Capacity (L/S) | Clean Resistance Pa | Efficiency |

| H13AS1220610150 | 610 | 1220 | 150 | 890 @ 1.2M/S | 325 | H13 |

| H13AS610305150 | 305 | 610 | 150 | 213 @ 1.14M/S | 325 | H13 |

| H13AS610305290 | 305 | 610 | 290 | 470 @ 2.54M/S | 350 | H13 |

| H13AS610610150 | 610 | 610 | 150 | 452 @1.2M/S | 325 | H13 |

| H13AS610610290 | 610 | 610 | 290 | 945 @2.54M/S | 350 | H13 |

| H13AS915610150 | 610 | 915 | 150 | 670 @ 1.2M/S | 325 | H13 |

Specification

Series : Aluminium Separator type

Header : Box, Single, Double

Frame : Wood, Aluminium, Galvanised & Stainless Steel

Separators: Aluminium foil

Media : Wet – laid micro – glassfibre

Sealant : Polyurethance

Fire retardant : UL900

Temperature : < 80° C

Humidity < 100% RH

Efficiency :

MPPS : > 99.95% (H13);

DOP : > 99.97% @ o.3 µm

Advantage

These specially designed filters allow systems to control laminar air flow under high humidity. Hemmed edges on the aluminium reduce possible pleat damage. Low initial pressure of the media increases the life of filters. Filters meet UL class 900 fire codes.

Applications

These filters can remove a broad range of airborne contaminants. They can be used as final filters in hospital, aerospace, pharmaceutical and food processing industries. They can also be used as pre-filters for the most demanding clean rooms.