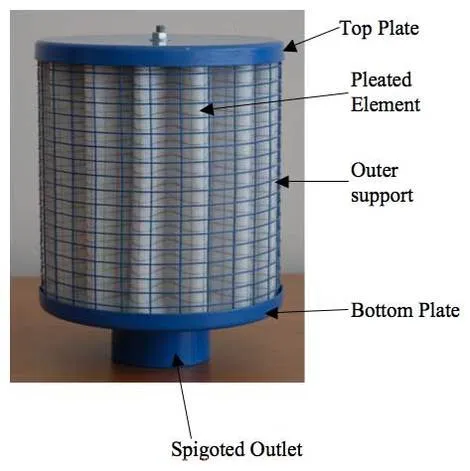

Circular Filters - with Spigot, Flange and Cowl

EXTENDED SURFACE VEEFORM FILTER MEDIA

Rainbow Filters design and manufacture a range of Standard Circular Filters for your requirements, as listed below. These solidly constructed circular filters can also be supplied with a variety of weatherproof cowls for both top and side mounting. Mounting Flanges when required are made from 3mm or 5mm flat steel, depending on the size of the filter. The spigot “if required” is made from 3mm x 50mm flat bar.

Downloads

Product list

| Code | Height (mm) | Diameter (mm) | Capacity (L/S) | Max Spigot Diameter (mm) | Efficiency |

| EAC30-FC | 152 | 254 | 255 | 153 | G4 |

| EAC31-FC | 216 | 355 | 496 | 254 | G4 |

| EAC32-FC | 317 | 457 | 958 | 355 | G4 |

| EAC33-FC | 395 | 533 | 1416 | 431 | G4 |

| EAC34-FC | 457 | 533 | 1652 | 431 | G4 |

| EAC35-FC | 508 | 610 | 1890 | 508 | G4 |

| EAC36-FC | 610 | 610 | 2360 | 508 | G4 |

| EAC37-FC | 610 | 864 | 3540 | 762 | G4 |

MAINTENANCE INSTRUCTIONS

RESISTANCE INDICATOR

Where a manometer is installed across the filter bank, the filter should be cleaned when the resistance is double the initial (clean) resistance, or when the resistance reaches 125 pascals.

Where a manometer is not employed, it is recommended that the filters are washed monthly for most general air conditioning applications. More frequent cleaning may be required if the installation is subject to high dust concentration.

WASHING

First remove the TOP PLATE from the Circular Filter Cell then the CRIMPED MEDIA may be removed and hosed with cold water from the clean air side. Shake out the excess moisture and replace the CRIMPED MEDIA in the Circular Filter. (It is necessary to remove the crimped media from the filter for washing).

REPLACING CRIMPED MEDIA

Remove the TOP PLATE from the Circular Filter and remove the old crimped media. Slide thE. new pleated element into position ensuring that the ends of the pleats seal evenly against thE bottom circular plate. Replace the TOP PLATE ensuring that the pleated element seals evenly against the top plate and that the plate is sitting squarely on the filter. It should not be necessary to remove the Circular Filter from its permanent position.